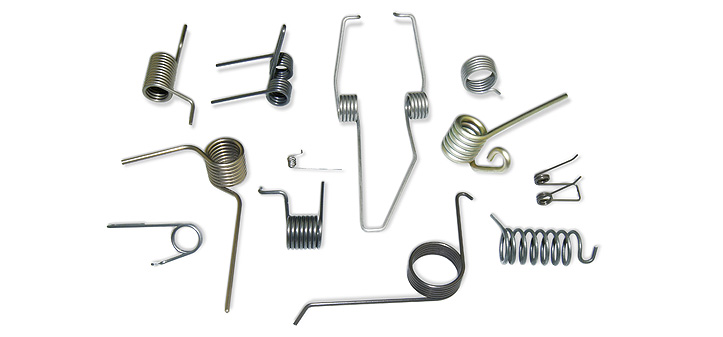

Torsion springs

Wherever torsional or rotational force is needed, torsion springs can be applied. Torsion springs are part of levers, fulcrums, switches and hinges and thus play an important role in mechanical and engineering and plant construction, automotive and electronics industry as well as numerous consumer goods.

Basically, torsion springs are helical shaped with ends that rotate in angular deflection. Each end is attached to other components, and when the components rotate around the spring's center point, the spring will try to push them back to their original position.

Depending on the application, we wind single torsion springs to work in either a clockwise or counter-clockwise rotation as well as double torsion springs with one coil wound clockwise and another coil wound counter-clockwise. We configure leg shape and position to achieve optimum force transmission for your unique application.

We set the properties of the springs to their optimum values with deburring, defined heat treatment and comprehensive tests to ensure compliance with tolerances and test specifications required by you.

We configure torsion springs as regards material, inner and outer diameter, leg style and leg orientation after individual calculation. Please contact us!

Technical details (Quality grade 1 and 2 according to DIN 2094)

Material

- Patented drawn steel wire (EN 10270-1)

- Stainless spring steel wire (EN 10270-3)

- Special materials such as Hastelloy, Nimonic

Wire diameter (d) from 0.8 to 5.0 mm

Pitch: Closely wound, equal pitch, progressive pitch

Direction of wind: Clockwise or counter-clockwise; double torsion springs with clockwise and counter-clockwise coiling

Leg style: Single or double torsion springs, closed ends, closed and ground ends, open ends

Leg orientation

- Tangential, axial, radial, radial/tangential

- Wound once or several times

Coatings and surface treatment

Electroplating, Delta Tone, Delta Seal, others on request